Internally equalized thermostatic expansion valves: A crucial component in refrigeration systems, these devices regulate refrigerant flow, ensuring optimal system performance and efficiency. Their unique design and operation set them apart from other types of expansion valves, offering distinct advantages and applications.

Embark on a comprehensive journey as we delve into the world of internally equalized thermostatic expansion valves, exploring their intricacies and significance.

Internally equalized thermostatic expansion valves: Their role in refrigeration systems cannot be overstated. They maintain the desired superheat at the evaporator outlet, ensuring efficient heat transfer and system stability. Their precise control over refrigerant flow optimizes system performance, reduces energy consumption, and prolongs component life.

As we delve deeper, we will uncover the inner workings, design considerations, and diverse applications of these remarkable valves.

Internally Equalized Thermostatic Expansion Valves: A Comprehensive Overview

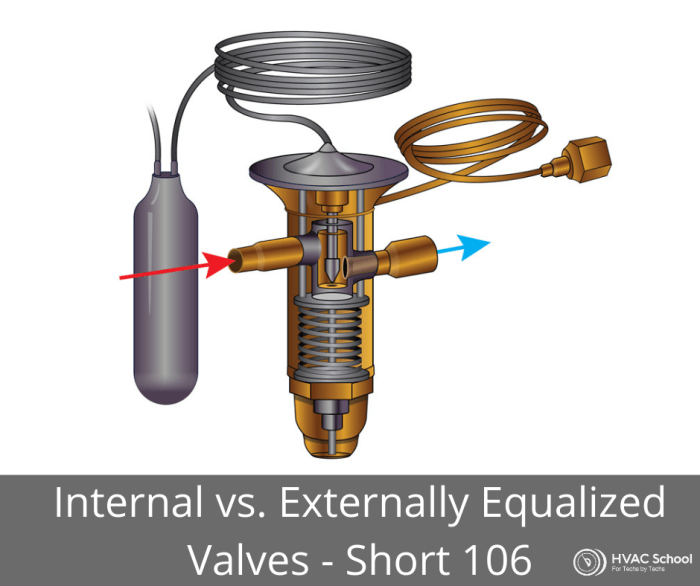

Internally equalized thermostatic expansion valves (TXVs) are a type of refrigerant control device used in refrigeration systems to regulate the flow of refrigerant into the evaporator. They are designed to maintain a constant superheat at the evaporator outlet, ensuring optimal system performance and efficiency.

The working principle of internally equalized TXVs involves a sensing element that is located in the evaporator outlet. This sensing element is typically a thermostatic bulb or capillary tube that is filled with a volatile liquid. As the temperature of the refrigerant increases, the pressure inside the sensing element also increases.

This pressure increase acts on a diaphragm, which in turn opens or closes a valve to control the flow of refrigerant.

Internally equalized TXVs offer several advantages over other types of expansion valves. They are relatively simple in design, have a wide operating range, and are able to maintain a constant superheat even under varying load conditions. However, they can be more expensive than other types of expansion valves and may require more maintenance.

Design and Construction of Internally Equalized Thermostatic Expansion Valves

Internally equalized TXVs consist of several key components, including:

- Sensing element: The sensing element is located in the evaporator outlet and is responsible for detecting changes in temperature.

- Diaphragm: The diaphragm is a flexible membrane that is actuated by the pressure inside the sensing element. It opens or closes the valve to control the flow of refrigerant.

- Spring: The spring provides a force that opposes the pressure inside the sensing element. The spring rate determines the superheat setting of the TXV.

The materials used in the construction of internally equalized TXVs include:

- Brass: Brass is a common material used for the body of the TXV. It is corrosion-resistant and has good thermal conductivity.

- Stainless steel: Stainless steel is used for the diaphragm and spring. It is corrosion-resistant and has good strength.

- Copper: Copper is used for the sensing element. It has good thermal conductivity and is easily formed.

The design and construction of internally equalized TXVs are influenced by several factors, including:

- Capacity: The capacity of the TXV is determined by the size of the sensing element and the spring rate. A larger sensing element and a weaker spring will result in a higher capacity TXV.

- Pressure: The pressure range of the TXV is determined by the materials used in its construction. A TXV made of stronger materials will be able to withstand higher pressures.

- Temperature range: The temperature range of the TXV is determined by the materials used in the sensing element. A TXV with a sensing element made of a material with a high melting point will be able to withstand higher temperatures.

Applications of Internally Equalized Thermostatic Expansion Valves: Internally Equalized Thermostatic Expansion Valves:

Internally equalized TXVs are used in a variety of refrigeration systems, including:

- Air conditioning systems: TXVs are used to control the flow of refrigerant into the evaporator of an air conditioning system. This helps to maintain a constant temperature in the conditioned space.

- Refrigeration systems: TXVs are used to control the flow of refrigerant into the evaporator of a refrigeration system. This helps to maintain a constant temperature in the refrigerated space.

- Heat pumps: TXVs are used to control the flow of refrigerant into the evaporator of a heat pump. This helps to maintain a constant temperature in the heated space.

Internally equalized TXVs offer several advantages over other types of expansion valves in these applications. They are relatively simple in design, have a wide operating range, and are able to maintain a constant superheat even under varying load conditions.

Some real-world examples of the use of internally equalized TXVs include:

- In air conditioning systems, TXVs are used to control the flow of refrigerant into the evaporator of a central air conditioner. This helps to maintain a constant temperature in the home.

- In refrigeration systems, TXVs are used to control the flow of refrigerant into the evaporator of a commercial refrigerator. This helps to maintain a constant temperature in the refrigerated display case.

- In heat pumps, TXVs are used to control the flow of refrigerant into the evaporator of a geothermal heat pump. This helps to maintain a constant temperature in the home.

Troubleshooting and Maintenance of Internally Equalized Thermostatic Expansion Valves

Common problems that can occur with internally equalized TXVs include:

- Superheat is too high: This can be caused by a weak spring, a damaged sensing element, or a clogged capillary tube.

- Superheat is too low: This can be caused by a strong spring, a damaged sensing element, or a leak in the diaphragm.

- The TXV is not opening: This can be caused by a stuck valve, a damaged diaphragm, or a clogged capillary tube.

- The TXV is not closing: This can be caused by a weak spring, a damaged diaphragm, or a leak in the sensing element.

Troubleshooting and repairing internally equalized TXVs involves the following steps:

- Check the superheat: Use a temperature probe to measure the superheat at the evaporator outlet. If the superheat is too high or too low, adjust the spring rate or replace the sensing element.

- Check the valve: Remove the TXV from the system and check the valve for damage. If the valve is damaged, replace the TXV.

- Check the diaphragm: Remove the diaphragm from the TXV and check it for damage. If the diaphragm is damaged, replace the TXV.

- Check the capillary tube: Remove the capillary tube from the TXV and check it for clogs. If the capillary tube is clogged, clean or replace it.

Preventive maintenance measures that can help extend the life and performance of internally equalized TXVs include:

- Regularly check the superheat and adjust the spring rate as needed.

- Inspect the valve and diaphragm for damage and replace them as needed.

- Clean or replace the capillary tube as needed.

Future Developments and Trends in Internally Equalized Thermostatic Expansion Valves

Emerging trends and developments in the design and application of internally equalized TXVs include:

- The use of electronic controls: Electronic controls can be used to improve the performance of TXVs by providing more precise control over the superheat. This can lead to improved system efficiency and reduced energy consumption.

- The use of new materials: New materials are being developed that can improve the performance and durability of TXVs. These materials include high-strength alloys and corrosion-resistant coatings.

- The development of new designs: New designs are being developed that can improve the performance of TXVs in specific applications. These designs include TXVs with low pressure drop and TXVs with high capacity.

The potential benefits of these advancements include:

- Improved system efficiency

- Reduced energy consumption

- Improved reliability

- Longer service life

The challenges associated with these advancements include:

- Increased cost

- Complexity of design

- Availability of new materials

The future of internally equalized TXVs is bright. These devices are becoming more efficient, reliable, and durable. As new technologies are developed, TXVs will continue to play an important role in refrigeration systems.

Essential FAQs

What are internally equalized thermostatic expansion valves?

Internally equalized thermostatic expansion valves are self-contained devices that regulate refrigerant flow based on the superheat at the evaporator outlet. They maintain a constant superheat, optimizing system performance and efficiency.

How do internally equalized thermostatic expansion valves work?

Internally equalized thermostatic expansion valves use a sensing element to measure superheat. When superheat increases, the sensing element expands, reducing refrigerant flow. Conversely, when superheat decreases, the sensing element contracts, increasing refrigerant flow.

What are the advantages of internally equalized thermostatic expansion valves?

Internally equalized thermostatic expansion valves offer precise control over refrigerant flow, reduced energy consumption, improved system stability, and prolonged component life.